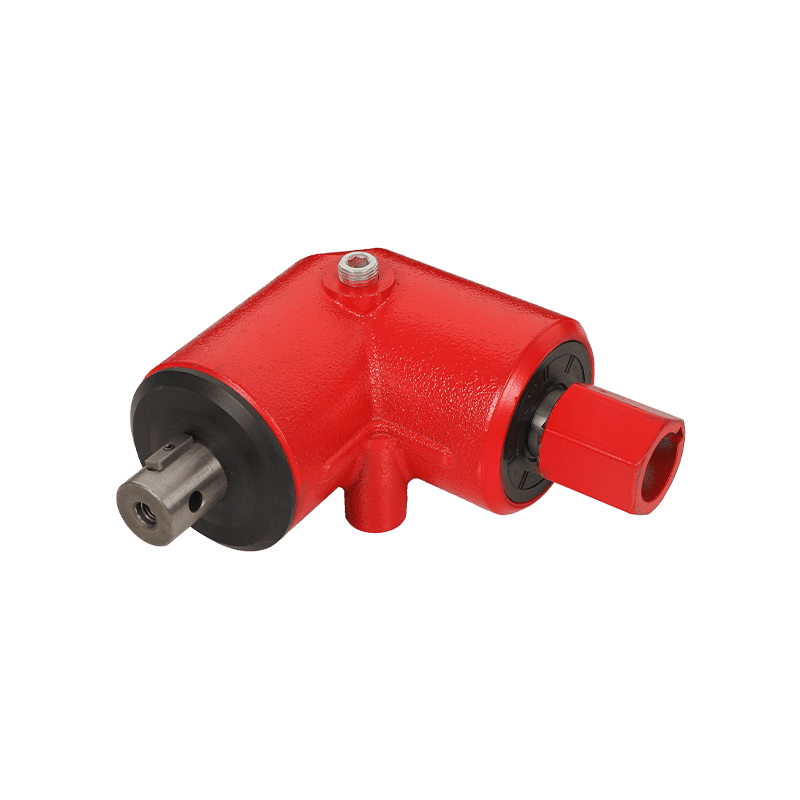

KLF190-R3 Seeder machine auger gearbox Reducer

Cat:Fertilizer Seeder Type Gearbox

This product can be used in conjunction with other products to transmit power through the drive shaft. Linked auger gearboxes, auger gearboxes can be ...

See DetailsWhen selecting the right fertilizer spreader gearbox for a fertilizer spreader, one of the most crucial decisions involves understanding the design and operational characteristics of the gearbox—specifically, whether it is a sealed or open-type model. The choice between these two designs can significantly impact the spreader’s performance, longevity, and maintenance needs.

Sealed Gearboxes: Maximizing Durability and Performance

Sealed gearboxes are a robust solution, designed to keep the internal components protected from external contaminants such as dust, dirt, and moisture. These types of gearboxes are hermetically sealed with gaskets or rubber seals that prevent any entry of foreign substances. This design is particularly beneficial in environments where the spreader operates under harsh conditions—such as in agricultural fields with high levels of fertilizer dust or where weather conditions vary.

The sealed design not only enhances the gearbox's durability but also minimizes the need for frequent maintenance. By keeping lubrication and oil contained within the gearbox, these units can run for extended periods without the need for re-lubrication, reducing downtime and maintenance costs. In industries that require machinery to perform consistently under demanding workloads, sealed gearboxes offer a significant advantage.

Furthermore, sealed gearboxes are generally more efficient when it comes to energy use. The tightly enclosed system reduces friction losses and optimizes the flow of power through the gearbox, which is essential for maintaining the spreader's efficiency. As a result, sealed gearboxes are typically preferred for commercial and heavy-duty fertilizer spreaders that demand high performance with minimal maintenance.

Open-Type Gearboxes: Cost-Effective but Less Protected

On the other hand, open-type gearboxes feature an exposed design that allows for easy access to the internal components. While they offer a cost-effective solution in certain applications, they are generally more vulnerable to wear and tear. Without the protective seals, dust, debris, and moisture can easily enter the gearbox, leading to potential contamination of the lubricant and accelerated wear on the gears.

For users who operate fertilizer spreaders in cleaner, less demanding environments, open-type gearboxes may be a suitable option. They allow for easy inspection and maintenance, which can be an advantage in situations where the spreader operates in controlled or less challenging conditions. Additionally, the open design allows for the quick replacement of parts or adjustments, which can be appealing to those who prefer to make on-site repairs without relying on specialized technicians.

However, the lack of a sealed environment means that open-type gearboxes generally require more frequent maintenance and lubrication. The exposure to environmental elements can result in a reduced lifespan for the gearbox if not properly cared for, leading to higher long-term operational costs. For this reason, open-type gearboxes are typically found in smaller-scale or less-intensive applications where cost-efficiency is prioritized over longevity and durability.

Which Design Is Right for You?

The decision to choose a sealed or open-type gearbox ultimately depends on the specific requirements of your fertilizer spreader. If your operations are intensive, with high demands on the machinery and frequent exposure to challenging environmental conditions, a sealed gearbox is the more appropriate choice. It provides enhanced protection, greater reliability, and lower long-term maintenance costs.

Conversely, if your spreader operates in relatively clean environments with lighter usage and cost is a significant concern, an open-type gearbox may serve your needs effectively. However, it’s important to understand that the lack of sealing could result in higher maintenance and shorter lifespan over time.